The CustomWater Process

Talk to our experts at CustomWater.com

- +1 (877) 891-4274

Loved by our Customers

Bottled to the highest standards

Order Process

After discussing your project needs and receiving your logo, we can handle the rest.

01

Label Design

Select your bottle size, your water type, and label style. Then let us know how many cases or bottles you're looking for.

02

Bottling

With bottling plants across America, we can ship faster than the competition and save you money.

03

Label Application

We apply your labels to the bottles. High quality. Waterproof. UV resistant. Fridges, Ice buckets, you name it. Great for all occasions.

04

Packing

Perfect for retail stores, franchises, hotels and large events. Special discounts available on recurring, bulk and truckload orders.

05

Distribution / Delivery

With bottling plants across America, we can ship faster than the competition and save you money.

We take care of everything!

This might be your first rodeo, but it sure ain't ours. We'll handle each task, start to finish, so you don't have to.

Once you give us the green light and a few details, you can sit back and relax. In just a short amount of time you will have a refreshing bottle advertising your business.

Bottled Water at Great Prices

Take advantage of our great wholesale pricing. The more water bottles with labels you buy, the better the bottle cost.

We Design your Custom Labels

Our art team creates your label to your exact standards. Your brands colors, logos, photos and info are front and center.

We Apply your Custom Labels

All the work is done for you. When your labeled water bottles arrive they are filled with drinking water and ready to enjoy!

We Ship

Everywhere

With multiple bottled water facilities located throughout the USA, we make shipping your corporate water bottles fast and easy.

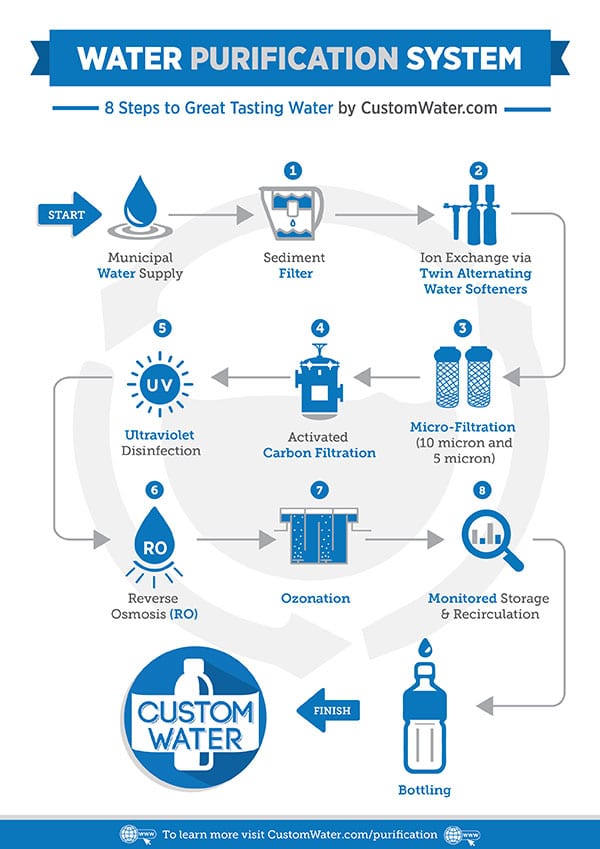

Custom Water Purification Process

Custom Water utilizes a state of the art purification system for our custom labeled bottled water. Read on for more about our process to great tasting purified water.

We begin our purification process from the Municipal Water Supply. This source is very similar to the drinkable water that comes into your home and is considered safe to drink. We strive to a higher standard and run everything through our specialty systems to insure you get nothing but the best tasting water.

-

Sediment Filter

Early on in the process we trap and remove the larger particles in the water (ie. sand, dirt, slime etc.). This insures that these items do not damage our filtration system and also increases the speed at which the purification can take place.

-

Ion Exchange with Twin Alternating Water Softeners

Our Twin Softeners remove heavy metals such as lead, mercury iron and cadmium from the water.

-

Activated Carbon Filtration

Commonly known as Charcoal filtration, this phase removes Chlorine, Pesticides and Herbicides from the water.

-

Micro Filtration

We utilize a dual filter system that are sized 10 micron and 5 micron. These filters trap and remove any tiny particles.

-

Ultraviolet Disinfection

Ultraviolet light sterilizes bacteria, viruses and microbiological contaminants (if present). If found they then transfer to the drain.

-

Reverse Osmosis (RO)

Pressure is applied to spread the water across a semi-permeable selective membrane. During this stage any impurities are left behind as the membrane allows only pure water through. Impurities that are caught become concentrated and sent to the drain.

-

Ozone Injection

Ozone is added to water to remove oxygen and provide a final step of disinfection of the water and anything it touches. Ozone is chemical free and is based on taking O2 (molecular oxygen) and through high voltage electricity, the molecule is split and recombined to form Ozone (O3). Ozone is used because it is far superior to Chlorine on many levels. First, its significantly more effective in cleansing and sanitizing (about 1500x better). Second, it is tasteless and colorless, and after 24 minutes of application to water, returns back to Oxygen (O2) again.

-

Storage and Re-circulation

Water travels through a re-circulation loop while waiting to be bottled. While we have two tanks full of purified water ready to be bottled at any time, we like to keep everything moving.

Ready for Bottling!

Now that our water has completed an intensive purification phase, we can begin bottling and labeling. Each of these steps help insure that only the best tasting, purest water ever touches your lips, or those of your customers.